Projects

1.Proiectul LIMESYS - Development of new LIght Mechatronic SYStems based on dynamics and control optimisation

The project was funded by the European Commission between 2004-2008, Project manager: Prof. dr. eng. Deaconescu Tudor.

Project description: The objective of the project was to develop innovative, lightweight mechatronic systems with improved dynamics.

- New drive systems based on pneumatic muscles were designed and studied.

- One consequence of this Contract was the establishment of the Research Center in the field of actions and automation of FESTO.

Project members: Prof. dr. Eng. Deaconescu Tudor, Prof. dr. Eng. Deaconescu Andrea, Prof. dr. Eng. Calefariu Gavrilă, Assoc. prof. dr. eng. Chivu Catrina, Lect. dr. eng. Chivu Cătălin, Assoc. prof. dr. eng. Pisarciuc Cristian.

2. Research on the performance of pneumatic muscles used in the operation of non-anthropomorphic robot prehensors

Project members: Prof. dr. Eng. Deaconescu Tudor, Prof. dr. eng. Deaconescu Andrea, Assoc. prof. dr. eng. Chivu Catrina, Lect. dr. eng. Chivu Cătălin.

Project members: Prof. dr. Eng. Deaconescu Tudor, Prof. dr. eng. Deaconescu Andrea, Assoc. prof. dr. eng. Chivu Catrina, Lect. dr. eng. Chivu Cătălin.

3. Development of rotational and translational modules for rehabilitation robots, driven by pneumatic muscles.

Contract CNCSIS - IDEI, PN-II-ID-PCE-2007-1, ID_184, Project manager: Prof. dr. eng. Andrea Deaconescu

Description of the project: The project was funded by CNCSIS between 2007-2010 and consisted in the design, implementation and testing of rotational modules (shoulder, elbow, hand) and translation modules, usable in the construction of rehabilitation robots.

- The arm of such robots can be placed on a wheelchair or at work.

- The novelty of the products is their mode of action, based on pneumatic muscles.

Project members: Prof. dr. eng. Deaconescu Andrea, Prof. dr. eng. Deaconescu tudor, Lect. dr. eng. Ichim Izabella, Lect. dr. eng. Limbaşan Georgiana

Project members: Prof. dr. eng. Deaconescu Andrea, Prof. dr. eng. Deaconescu tudor, Lect. dr. eng. Ichim Izabella, Lect. dr. eng. Limbaşan Georgiana4. Isokinetic equipment operated with pneumatic muscles, intended for the recovery of patients with post-traumatic diseases of the supporting joints.

Contract CNCSIS - IDEI, PN-II-ID-PCE-2008-2, ID_764. Project manager: Prof. dr. eng. Deaconescu Tudor

The project was funded by CNCSIS between 2008-2010 and aimed to design, manufacture and test an isokinetic equipment designed to perform continuous passive rehabilitation movements of the lower limb (hip, knee, ankle) joints. The equipment is operated with the help of the pneumatic muscles, which gives the absolute novelty of the proposed solution.

Project members: Prof. dr. eng. Deaconescu Andrea, Prof. dr. eng. Deaconescu Tudor, Lect. dr. eng. Ichim Izabella, Lect. dr. eng. Limbaşan Georgiana

Project members: Prof. dr. eng. Deaconescu Andrea, Prof. dr. eng. Deaconescu Tudor, Lect. dr. eng. Ichim Izabella, Lect. dr. eng. Limbaşan Georgiana

5. Theoretical and applied research regarding the dimensioning, configuration and simulation of flexible manufacturing systems for the processing of circular shafts

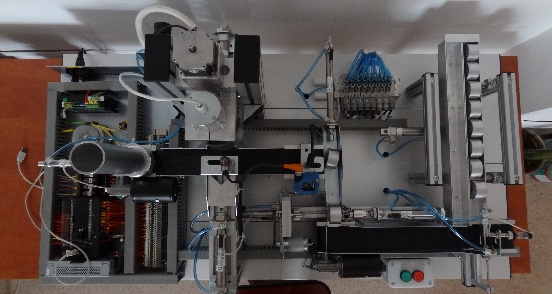

Description of the project: The research undertaken in the scientific research project was directed to study the Flexible Manufacturing Systems (FMS) in order to know their behavior and performances as best, and as possible, even before their physical realization, as well as to establish on a scientific basis the models of dimensioning, configuration and simulation of FMS, with concrete application in the field of circular shafts.

Project members: Prof. dr. eng. Florescu (Fota) Adriana, Prof. dr. eng. Calefariu Gavrilă, Prof. dr. eng. Buzatu Constantin, Scientific researcher dr. eng. Barabaș Sorin-Adrian, Lect. dr. ing. Găvruș Cristina, Lect. dr. ing. Barbu Magdalena.

Project members: Prof. dr. eng. Florescu (Fota) Adriana, Prof. dr. eng. Calefariu Gavrilă, Prof. dr. eng. Buzatu Constantin, Scientific researcher dr. eng. Barabaș Sorin-Adrian, Lect. dr. ing. Găvruș Cristina, Lect. dr. ing. Barbu Magdalena.

6. Control and pneumatic drive of the production systems

Project coordinator: Prof. dr. eng. Deaconescu Tudor

Project description: The purpose of the contract was to develop and present modern drive and automation solutions based on the use of pneumatic logic systems. A synthesis of the pneumatic sequential logic circuits was performed using the sequence logic modules and sequential cycles were designed on a single line and parallel lines.

Project members: Prof. dr. eng. Deaconescu Tudor, Assoc. prof. dr. ing. Ionescu Mihai