Infrastructure

• Maxiem 1530 abrasive jet cutting machine

• SLM250 additive manufacturing system

• 5-axis Mori Seiki NVX5080/40+5AX DDRT200 vertical machining centre

• CNC Goodway lathe

• Mitsubishi EDM FA105-A electro-erosion wire processing machine

• Steinbichler Comet L3D mobile scanner

• Mitutoyo equipment for dimensional control and measurement

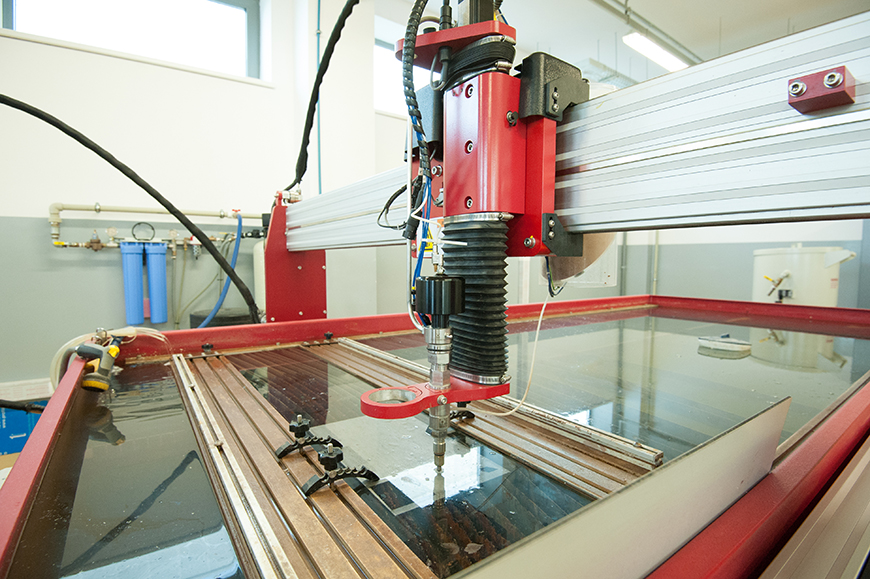

• Maxiem 1530 abrasive jet cutting machine

Two active horizontal axes X, Y, maximum abrasive jet pressure 350 Mpa, pump power 20 hp, maximum size 3800x1700 mm, working accuracy ± 0.1 mm

The equipment permits the cutting of flat pieces with complex contour, from various materials such as steel or non-ferrous materials, plastics, granite / marble, rubber, etc., in small series and prototypes.

• SLM250 additive manufacturing system

Table dimensions 250x250x250 mm, laser power 200W, materials: stainless steel, titanium alloy, cobalt/chrome alloy, layer thickness: 20 ... 50 µm

The equipment allows of additive manufacturing by metallic powder deposition by the SLM process - Selective Laser Melting of metal parts, in small series or prototypes.

• 5-axis Mori Seiki NVX5080/40+5AX DDRT200 vertical machining centre

Maximum speed: 15000 rpm, maximum stokes X/Y/Z: 800/530/510 mm, positioning accuracy: ± 0.0015 mm, repeatability: ± 0.0015 mm, HSK clamping system, DDRT200 rotary table, tool storage capacity: 30

The equipment allows of high precision milling of complex surfaces and other complementary operations such as drilling, boring, threading, by using various cutting regimes including HSM (high speed processing).

• CNC Goodway lathe

• Mitsubishi EDM FA105-A electro-erosion wire processing machine

• Steinbichler Comet L3D mobile scanner

Non-contact blue light by triangulation, 1600x1200 pixel resolution, minimum measurement volume 100x75x60 mm extensible to any size, speed 2Mp-2sec., scan accuracy 9 µm, rotary table for automatic positioning, Geomagic Studio management software included.

The equipment allows of 3D advanced blue light technology scanning of parts, being portable for an easy handling.

• Mitutoyo equipment for dimensional control and measurement

MitutoyoEuro C544A CMM measuring contact machine, measuring range X –axis = 505mm, Y –axis = 405mm, Z –axis = 405mm, linear measurement accuracy 0.0001 mm; Mitutoyo Quick Image Vision optical measuring system, X-axis = 300mm, Y-axis = 170mm, Z = 90mm, linear measurement accuracy: 0.1 µm, Mitutoyo LH600E digital vertical measuring column, digital dimensional and surface roughness measuring equipment: callipers, micrometers, comparator clocks, track sets, wireless data transmission system.