Products and services with innovative potential

Synthesis and processing of materials

The main areas of activity within this field are the synthesis and processing of metallic, ceramic and composite materials.

Metallic material synthesis involves the creation of alloys, intermetallic structures, and other structures with specific properties by combining elements and compounds through advanced physical and chemical techniques such as melting, casting, thin-film deposition, additive manufacturing, and nanoscale methods. Methods range from solid-state reactions of mixed metal powders to rapid solidification of molten alloys, which can produce amorphous materials, to highly controlled approaches such as laser-based additive manufacturing and solution-based chemical synthesis for nanoscale structures.

• Melting and solidification:

This traditional method involves melting metallic elements or powders and then controlling the cooling rate to form the desired solid structure, including creating metallic glasses (amorphous alloys).

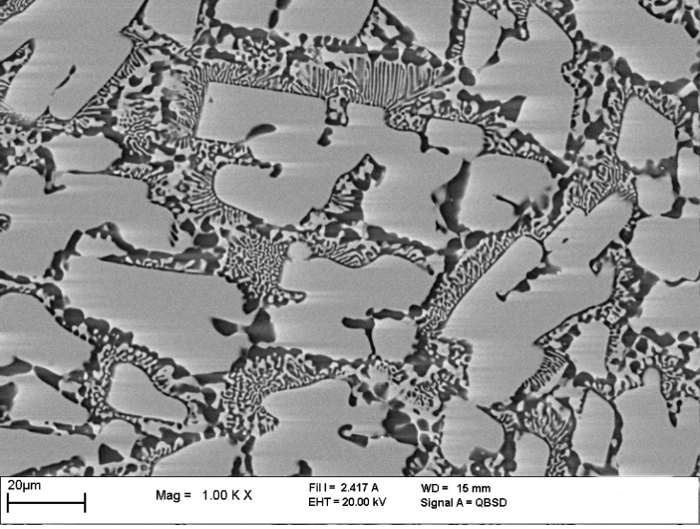

Microstructure of an AlCu35 alloy after gravitational casting

Ribbons with an amorphous structure obtained by melt-spinning, from AlCu10 alloy

• Solution-based synthesis:

Chemical reactions in a solution can be used to create various shapes of metallic and ceramic materials, including nanomaterials with well-defined shapes (nanoparticles, nanofilms, etc.).

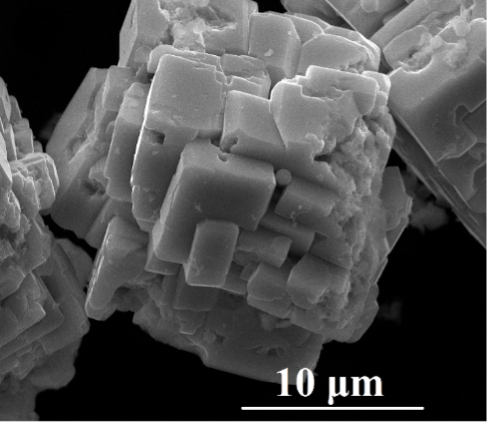

Bismuth ferrite powders prepared by hydrothermal method in a microwave field

• Powder metallurgy

Powder metallurgy is a manufacturing process that creates components from metal powders by mixing, compacting them into the desired shape, and then heating them below their melting point (sintering) to fuse the particles. Powders with various compositions and granulations can be produced by grinding in the planetary ball mill. In addition to obtaining powder materials, powders with special characteristics can also be obtained through the mechanical alloying process.

Cu-based metallic foam, obtained by powder metallurgy, using sodium chloride as a porogenic agent. The foam has potential in applications such as filtration, heat exchange or impact absorber.

• Deposition of thin films

Obtaining coatings involves depositing a material on a substrate, by physical, chemical or combined methods. Thin metallic, ceramic or composite layers can be obtained, both by thermal evaporation or magnetron sputtering, and by spin-coating or dip-coating. These layers are essential in technologies such as electronics, optics, and medicine to improve characteristics such as conductivity, hardness, durability, or optical transparency.

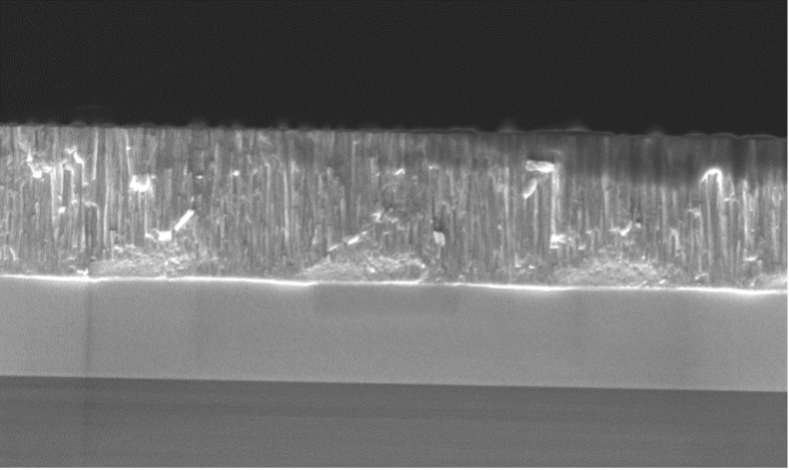

Chromium nitride thin film obtained by reactive magnetron sputtering, observed under a scanning electron microscope, in cross-section.

• Thermal treatments

The properties of materials are largely influenced by heat treatments. A thermal treatment involves the controlled heating and cooling of materials (metals, alloys, ceramics, etc) to modify their microstructure and improve mechanical properties such as hardness, strength, ductility, and wear resistance. Common processes include annealing (softening, increasing ductility), quenching (rapid cooling for hardness), tempering (reheating after quenching to reduce brittleness), and normalizing (heating above the critical temperature and free-cooling to change the shape and size of crystalline grains).

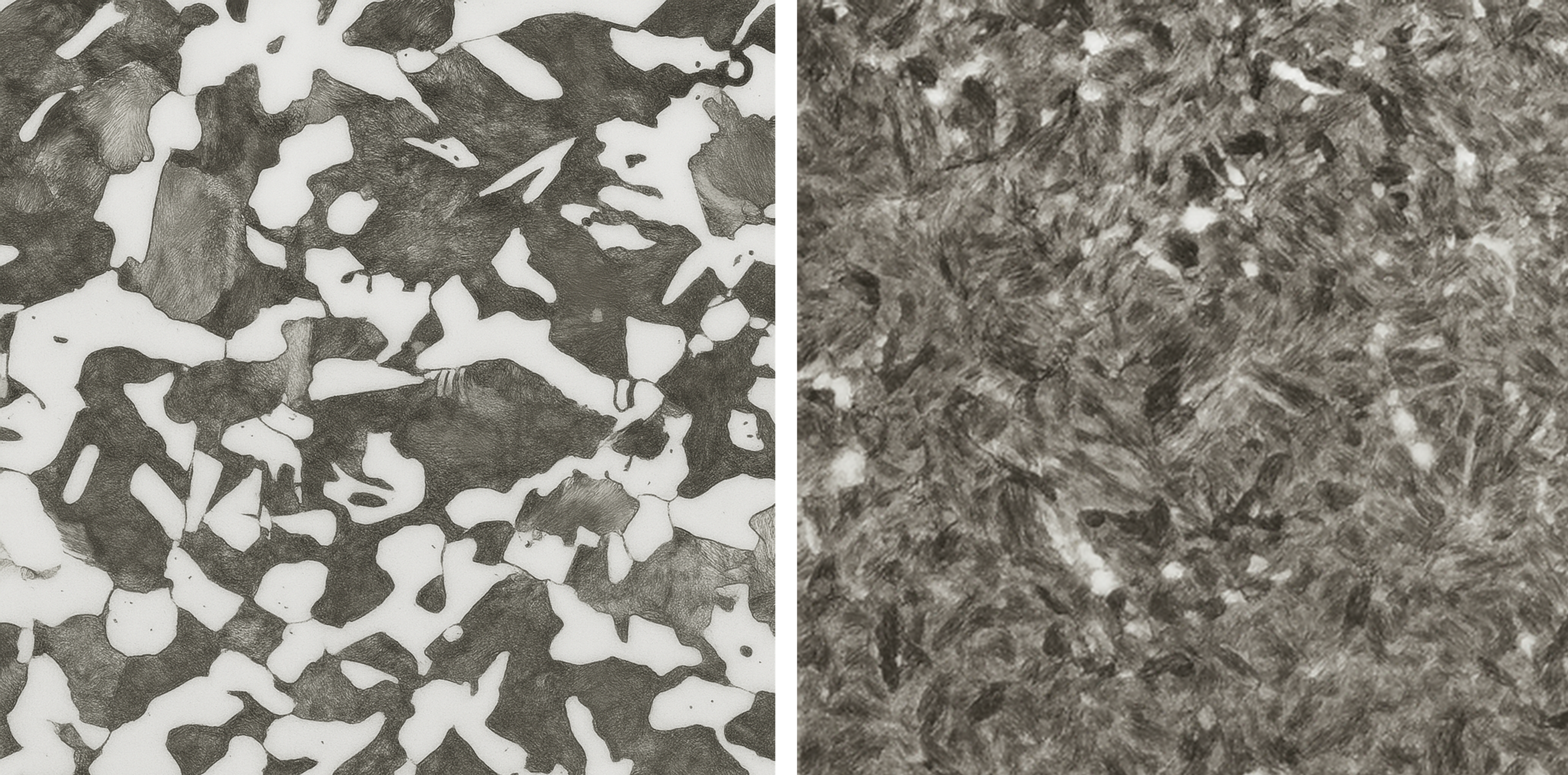

Microstructure of an EN 1.0503 steel before (left) and after quenching and tempering heat treatment (right). The heat treatment gives the material an optimal balance between hardness and toughness.

• Plastic deformations

Plastic deformation is the permanent and irreversible change in the shape of a material when it is subjected to stresses that exceed its flow limit. This process results from changes in the internal structure of the material. The properties of the material can be significantly different from those of the cast material, due to structural changes.

Steel samples, subjected to plastic deformation

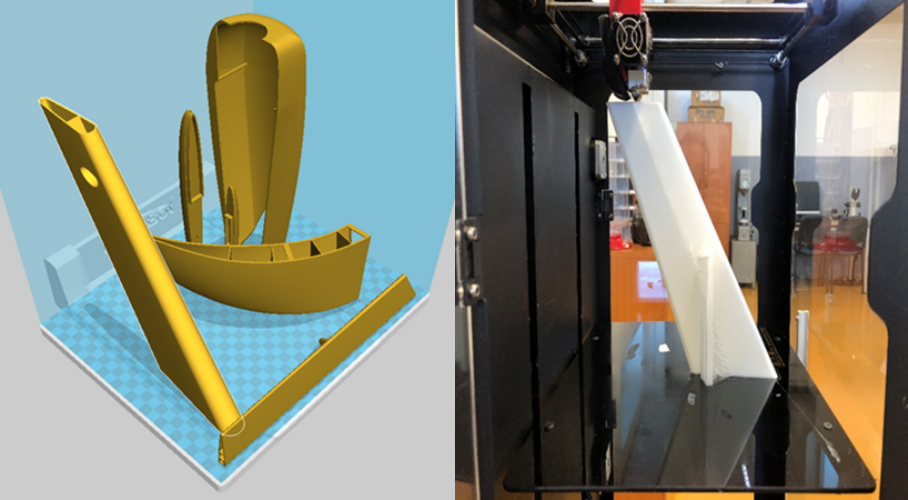

• Additive manufacturing

Additive manufacturing (3D printing) is a process that creates three-dimensional objects by depositing layer by layer of material from a digital design file, as opposed to traditional methods that involve removing the material. It uses various materials such as plastics, metals, ceramics, and composites to produce prototypes, custom parts, tools, and functional end products in industries such as automotive, aerospace, and medical.

Additively manufactured PLA Glass (fibreglass reinforced filament) elements for an unmanned aerial vehicle

Testing and characterization of materials

Testing and characterization of materials involves investigating the properties of materials, of a chemical, structural, morphological, mechanical, thermal, electrical nature, etc., to determine the performance of materials in various industries. Using both non-destructive and destructive testing, these practices evaluate the properties of materials to ensure that materials withstand operational requirements.

The infrastructure of the center allows:

• Determination of the chemical compositionof solid metal alloys based on iron, titanium, aluminum or copper.

Samples analyzed by optical spark emission spectrometry

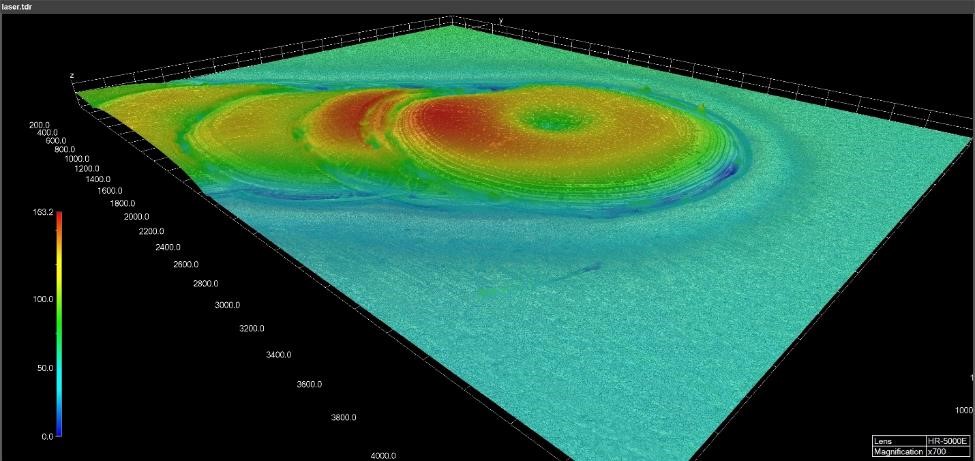

• Morphological and metallographic analysisat the macro and microscopic levels

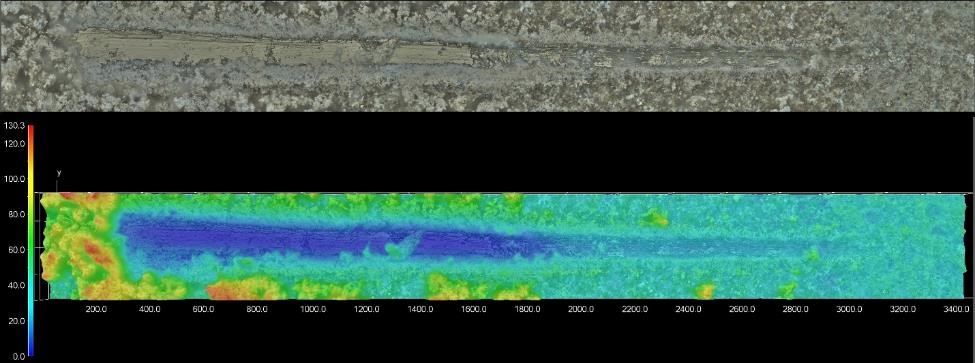

Morphology of a laser beam processed steel plate

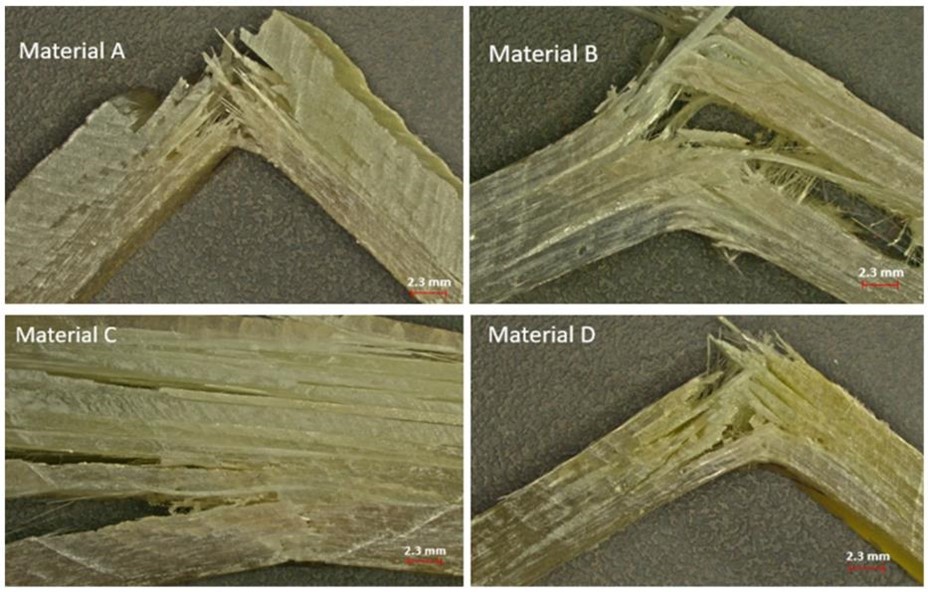

• Analysis of mechanical properties(tensile, compression, bending tests) at room temperature or in the temperature range -150 °C ÷ 1200 °C

Fiberglass reinforced polyester composites subjected to three-point bending tests

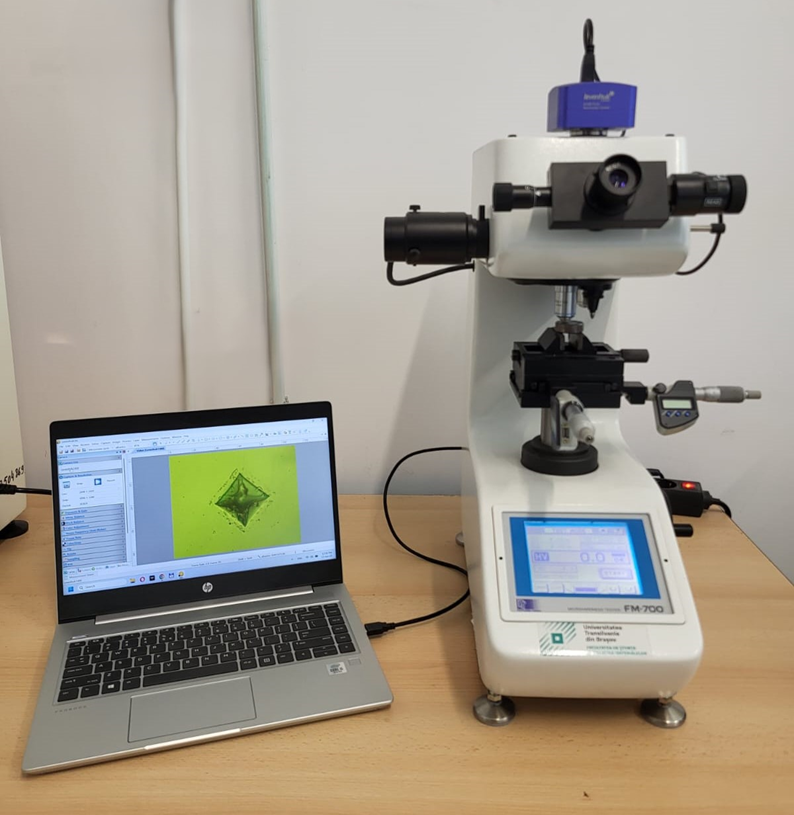

• Determination of the hardness of metallic and ceramic materials by various methods (Vickers, Rockwell, Brinell) and polymeric materials using the Shore method

Vickers geometry impression obtained on micro-hardness tester

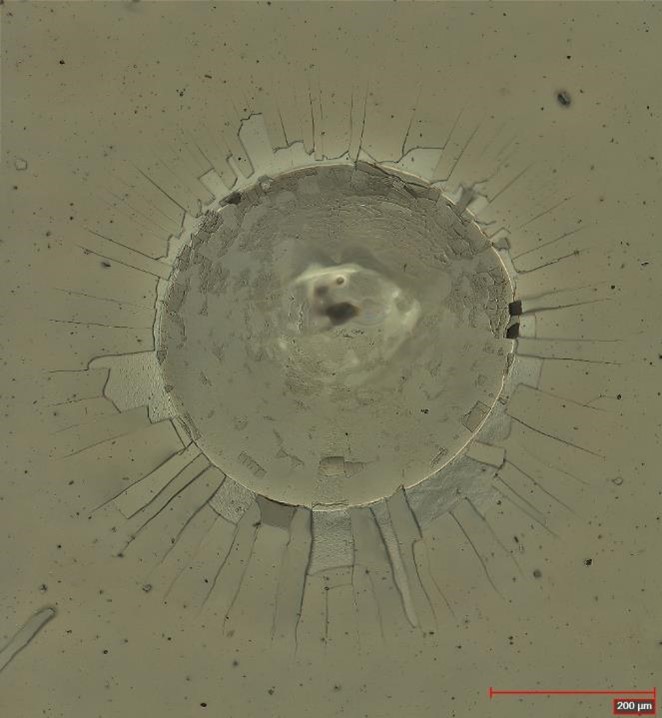

• Determination of the mechanical characteristics of surfaces or thin layers, by nanoindentation, microscratching (adhesion to substrate), wear resistance (tribology) under various conditions.

Microscratches on the surface of a coating obtained by Plasma Electrolytic Oxidation

Determination of adhesion to the substrate using the Mercedes method. Radial cracks and delaminations of the coating can be observed.

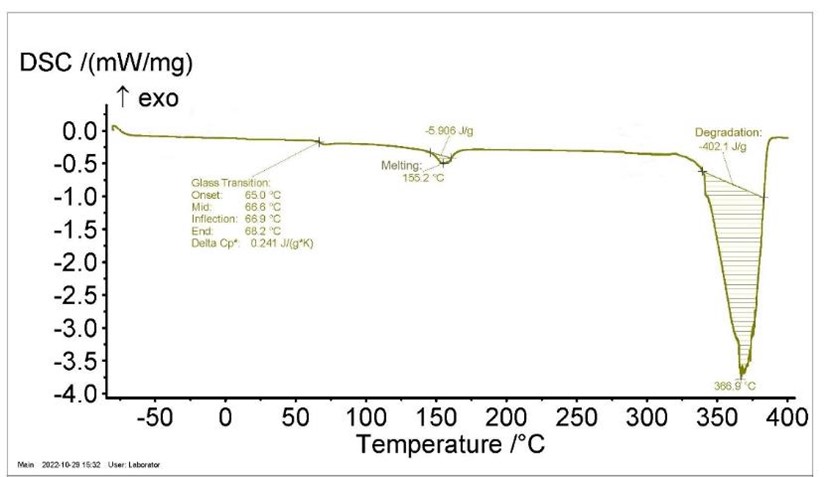

• Determination of the thermal properties of materials, with the help of dilatometry (RT – 1200°C), DSC – differential scanning calorimetry (-150 °C – 600 °C), DTA – differential thermal analysis, TG – thermogravimetric analysis (RT – 1600 °C).

Thermogram obtained by differential scanning calorimetry (DSC) for poly(lactic acid) (PLA - a polymer frequently used in biodegradable packaging and 3D printing technology), where the main physicochemical transitions are identified: the glass transition, associated with the softening of the material, the melting process and the thermal degradation stage.

• Determination of corrosion resistance, by accelerated corrosion tests or by electrochemistry tests

The effect of corrosive atmosphere on a high-speed steel, depending on the exposure time.

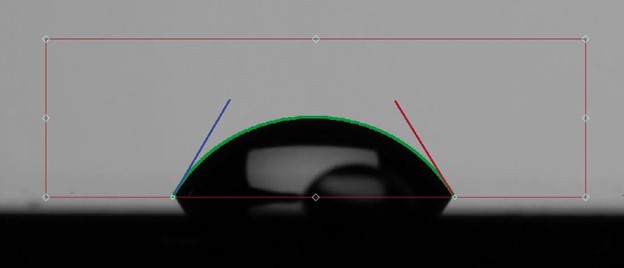

• Determination of surface optical characteristics (color, reflectance) and wettability

Determination of the contact angle of a solution on a surface.

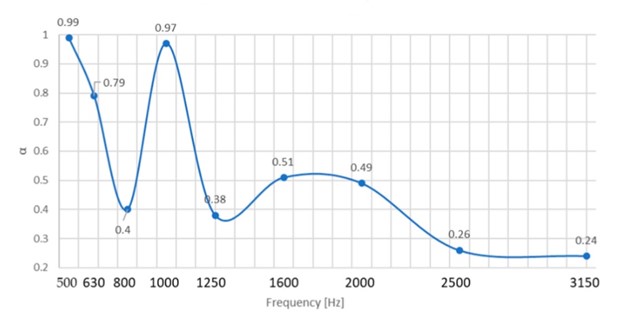

• Determination of the acoustic characteristics of materials, with the help of an impedance tube

Variation of the sound absorption coefficient as a function of frequency, for a sound-absorbing panel obtained by additive manufacturing

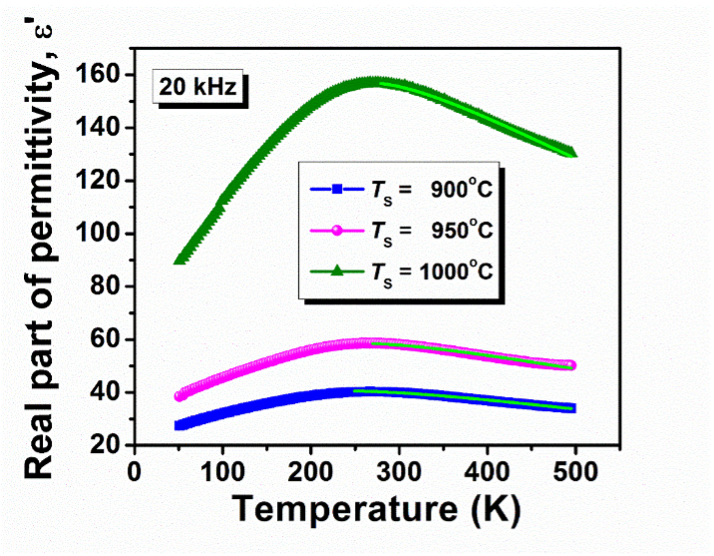

• Determination of the electrical characteristics of materials (resistivity, dielectric behavior, etc.).

Temperature dependence of the real part of the ε′(T) permittivity recorded at a frequency of 20 kHz for Bi0.2K0.2Ba0.2Ca0.2Sr0.2TiO3 high-entropy ceramics strengthened by conventional sintering at different temperatures