Projects

• Ecological composites made using 3D printing techniques to obtain sound-absorbing panels (PN-III-P1-1.1-TE-2021-0294)

The main goal of the project was to obtain sound-absorbing panels with high properties, namely: I) Obtaining sound-absorbing panels from recycled eco-composite materials (with a cellulose core and reinforced with a mixture of beeswax / fir resin / horsetail powder); ii) obtaining 3D printed sound-absorbing panels from biodegradable and ecological materials. The best results were obtained in the case of eco-composite panels, panels with a sound absorption coefficient α = 0.99, that are the subject of national patent application 2024 00099 and international patent application PCT/RO2024/000011.

Project members:

- CS II dr. eng. Mihai-Alin POP - Project Director

- Assoc. Prof. dr. eng. Cătălin CROITORU

- Lect. dr. eng. Sebastian-Marian ZAHARIA

- CS II dr. eng. Mihaela Codruța COȘNIȚĂ

- Lect. dr. eng. Cosmin SPÎRCHEZ

- CS dr. eng. Simona Corina MATEI

• Magnetron sputtered Me-Me binary oxynitride multifunctional thin solid films (PN-III-P1-1.1-TE-2019-1209)

The aim of the project was to study the chemical, structural, morphological variation and, consequently, the properties of multi-component oxynitride thin films based on Me1/Me2, where Me1 = Ta, Zr and Me2 = Ti (e.g., TaTiON, ZrTiON), obtained by simultaneous sputtering of two metal targets (high purity Ti, Ta, Zr), with the addition of different proportions of reactive gases (N2 and O2). The elements were chosen according to their atomic radius, in order to obtain distorted crystal lattices, which could lead to the variation of properties (e.g., increased hardness). The studied coatings based on ZrTiON and TaTiON revealed significant results in terms of their potential as multifunctional materials (photocatalysis, corrosion-resistant coatings, coatings with improved mechanical properties, etc.), depending on the processing parameters.

Project members:

- Dr. eng. Daniel CRISTEA – project director

- Dr. eng. Cătălin CROITORU

- Dr. eng. Camelia GABOR

- Dr. eng. Ioana GHIUȚĂ

- Dr. phys. Ioana-Laura VELICU

- Dr. phys. Vasile TIRON

- Dr. eng. Alexandru Horia MARIN

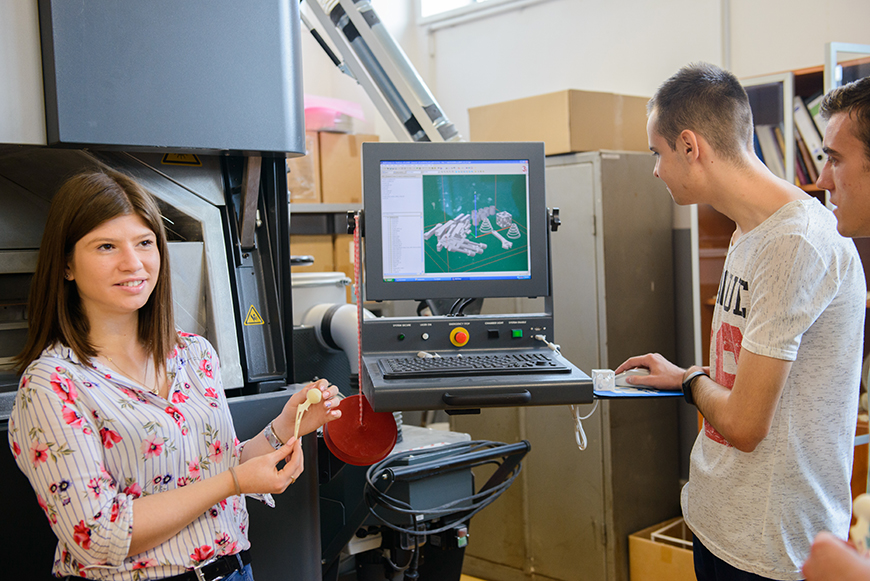

• Driving up Reliability and Efficiency of Additive Manufacturing (DREAM – Horizon 2020)

The aim of the DREAM project was to significantly improve the performance of the manufacturing process by PBF (Powder Bed Fusion), to obtain titanium, aluminum and steel components concomitantly with the increase of their fatigue resistance and working duration. The objective of the project was to go beyond the present status of the laser-based technology by mastering every step of the processing chain. Among the various industrial applications of PBF, the project was focused on components for prostheses, automotive parts and injection molding, in order to improve the fabrication process for titanium, aluminum and steel parts. The project started on the 1st of October 2016, over a period of 36 months. It was an international HORIZON 2020 project, and Transilvania University of Brașov was a partner in the consortium.

Project Members:

- Prof. Dr. Eng. Daniel MUNTEANU – project responsible for UTBv

- Assoc. Prof. Dr. Eng. Sorin MUNTEANU

- Assoc. Prof. Dr. Eng. Tibor BEDŐ

- Lecturer Dr. Eng. Daniel CRISTEA

- Lecturer Dr. Eng. Camelia GABOR

- Scientific Researcher III Dr. Eng. Mihai Alin POP

- Prof. Dr. Eng. Béla VARGA

- Dr. Eng. Ioana GHIUȚĂ

• Optimisation of the Ecotechnology of Induction Hardening of Large Diameter Bearing Rings (Bridge Grant)

The general objective of the project was to optimize the technological parameters of the induction hardening of the bearing rings, specifically the decrease by about 30% of the refuse. The specific objectives were to find the technological conditions that lead to defects; to rate the risk factors and to plan the reaction methodology; to implement the findings of the heating/cooling processes by new geometries of inductors which consider the new configurations of bearing rings. The desired outcome was to obtain a hardened layer on the active surface of the bearing ring which is uniform both in diameter as well as in section, having a pre-established thickness. The financing Institution was The Executive Unit for Financing Higher Education, Research, Development and Innovation (Unitatea Executivă pentru Finanțarea Învățământului Superior, al Cercetării, Dezvoltării şi Inovării, CNCS-UEFISCDI). It was a BRIDGE project, which had the duration of 24 months: from 30.09.2016 to 30.09.2018.

Project Members:

- Prof. Dr. Eng. Daniel MUNTEANU – project manager

- Assoc. Prof. Dr. Eng. Sorin MUNTEANU

- Lecturer Dr. Eng. Daniel CRISTEA

- Assoc. Prof. Dr. Eng. Tibor BEDŐ

- Lecturer Dr. Eng. Camelia GABOR

- Scientific Researcher III Dr. Eng. Mihai Alin POP

- Prof. Dr. Eng. Ioan MILOȘAN

• Industrial Research Services Structure Surface Implant: Mechanical Features – DENTIX

The main objective of this project was to conduct research on the structure of the surface of dental implants. Research of the mechanical features of both the material and the proper implant has been undertaken. From the perspective of the mechanical resistance and the reaction with the adjoining tissues, titanium responds best to the requirements of the living organisms. Titanium can be used in stomatology both in pure state as well as an alloy. Pure titanium meets the necessary requirements of a dental implant. The most important of its properties is the fact that it is corrosion resistant, due to the titanium dioxide layer that forms in contact with the environment, its thickness growing proportionally with the exposure duration. The continuous regeneration of this layer is what makes titanium corrosion resistant. The project was won in public tender for research services organized by Dentix Millenium SRL.

Project Members:

- Assoc. Prof. Dr. Eng. Sorin MUNTEANU – project manager

- Prof. Dr. Eng. Aurel CRIȘAN

- Prof. Dr. Eng. Béla VARGA

- Prof. Dr. Eng. Virgil GEAMĂN

- Assoc. Prof. Dr. Eng. Tibor BEDŐ

- Lecturer Dr. Eng. Daniel CRISTEA

- Lecturer Dr. Eng. Camelia GABOR

- Scientific Researcher III Dr. Eng. Mihai Alin POP

• Driving up Reliability and Efficiency of Additive Manufacturing – Premiere H2020

The aim of the project was to study the effect of the building direction by additive manufacturing on the anisotropy of plastic components regarding a series of mechanical properties (hardness, elastic modulus, tensile resistance, fatigue, and others). The properties of the components obtained by additive manufacturing vary according to the type of manufacturing process, as there are many methods of 3D printing, each having advantages and disadvantages. Porosity favors the propagation of fissures, thus affecting the mechanical properties of the components. For this reason, the main objective of the optimization of the additive manufacturing process is to obtain density of over 99.5% for the components. The optimal functioning characteristics of the components largely depends on the direction of construction and the position in the working space, because, as a rule, the powder present in the working space is considered partially used even if it is not sintered during the process. The project unfolded between 2017 and 2019.

Project Members:

- Prof. Dr. Eng. Daniel MUNTEANU – project manager

- Assoc. Prof. Dr. Eng. Sorin MUNTEANU

- Lecturer Dr. Eng. Daniel CRISTEA

- Assoc. Prof. Dr. Eng. Tibor BEDŐ

- Lecturer Dr. Eng. Camelia GABOR

- Scientific Researcher Dr. III Eng. Mihai Alin POP