Infrastructure

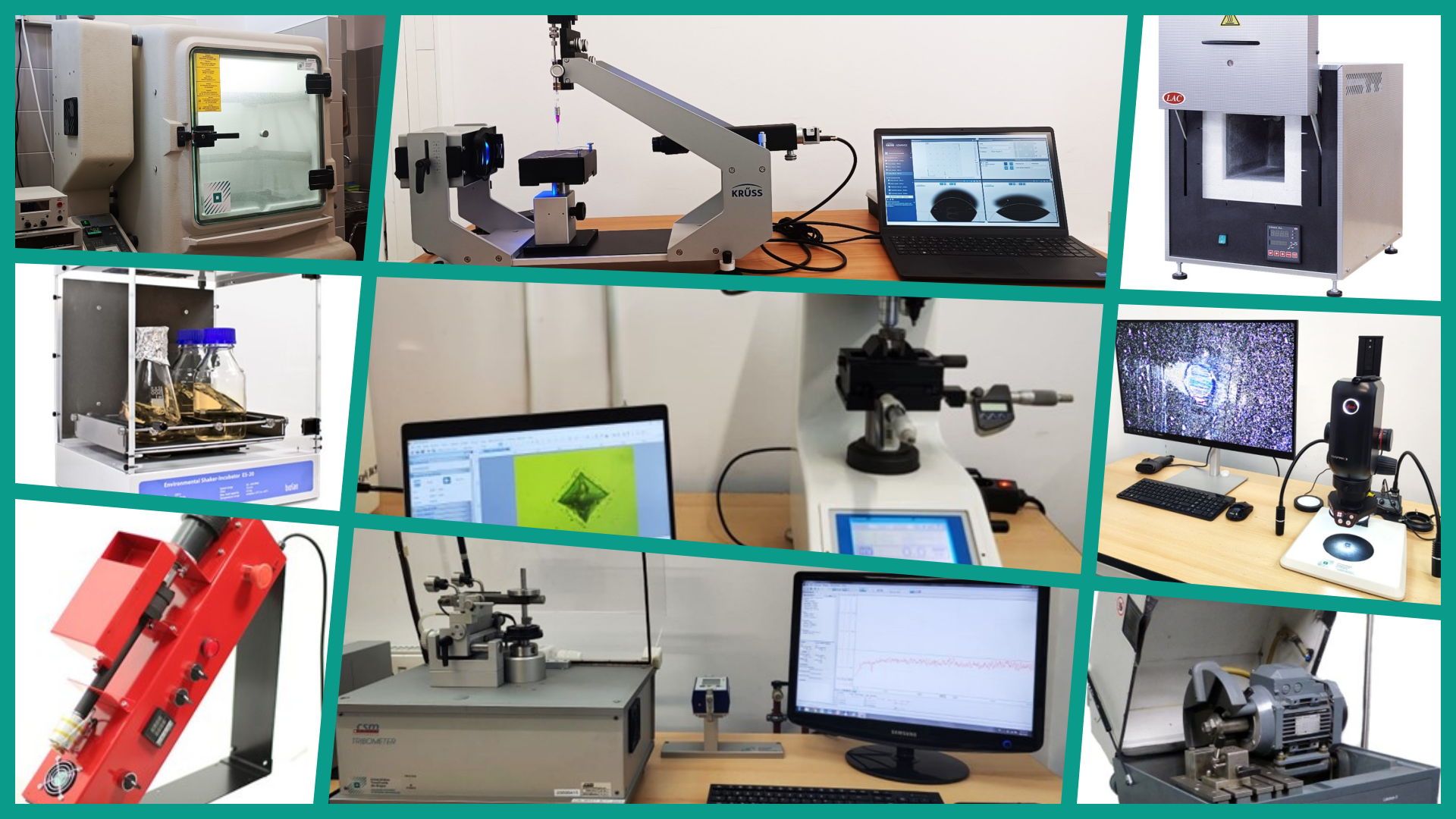

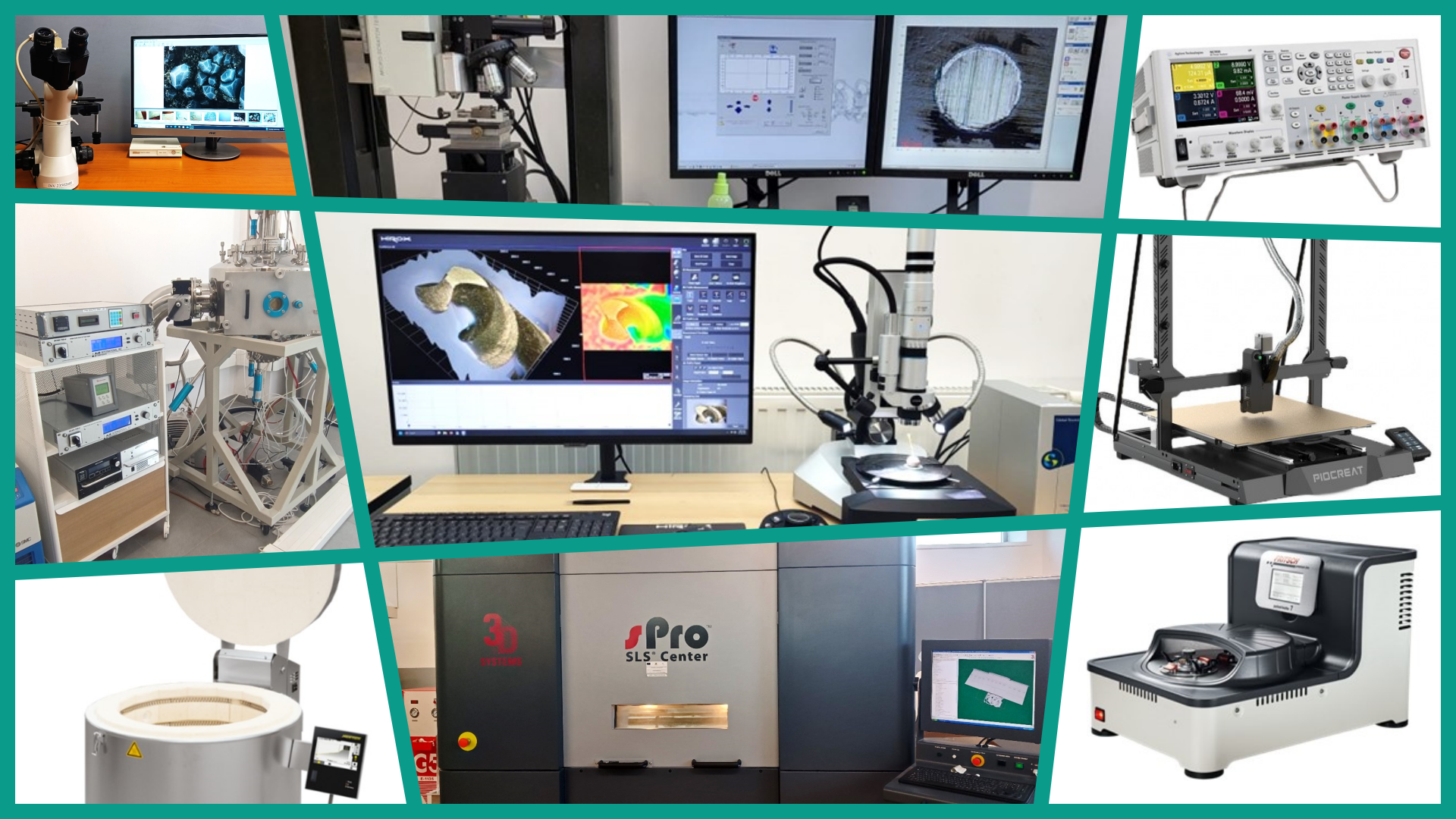

The Research Center for Advanced Metallic, Ceramic and Composite Materials and Technologies integrates specialized infrastructures for the synthesis and processing of materials, such as melting, heat treatment or sintering furnaces, plastic deformation equipment, powder metallurgy installations, equipment for obtaining thin layers by physical or chemical methods, devices for obtaining nanopowders by biological or chemical methods, respectively additive manufacturing installations using various technologies: selective laser sintering (SLS), filament deposition modeling (FDM), stereolithography (SLA), etc.

The Research Center also has specialized infrastructures for advanced material characterization: optical or digital microscopes, mechanical testing equipment, durometers, thin layer characterization equipment, thermal analysis equipment, spectrophotometers, corrosion resistance testing equipment, equipment for determining electrical properties.

The complete list of equipment is available HERE.

Induction furnace. Maximum installed power 20kW, frequency 15kHz and crucible working volume of 1-1.2 dm3. Allows processing in a stamped or removable crucible (graphite or ceramic) of ferrous and non-ferrous alloys or special materials (special alloys, composites, etc.). By using the experimental melt-spinning facility, one can produce metallic glass or amorphous alloys in the form of strips/ribbons.

Nabertherm 04/17 type furnace for heat treatment. This equipment can be used to perform special heat treatments and sintering for metallic and non-metallic (oxide) materials and alloys. It is an electric resistance furnace with a working temperature of up to 1750 °C and it enables the programming of heat treatment diagrams. It is also possible to control the working atmosphere, by gas purging.

Nabertherm Top 80 type furnace for melting, sintering, or heat treatment, with vertical loading, with a maximum temperature in the furnace chamber of 1320 °C. It has two internal thermocouples for temperature monitoring and a display panel for parameters or heating or cooling curves.

Memmert UF75 is a 74-liter forced convection laboratory oven designed for precise heating and drying applications in research, industry, and quality assurance. It has a temperature range from +10 °C above the ambient temperature to 300 °C.

LAC LMH 04/12 muffle furnace is a piece of lab equipment designed for high-temperature heat treatments (up to 1100 °C), using the muffle technique to ensure a controlled combustion or incineration environment. It is frequently used in fields such as analytical chemistry, metallurgy, materials research, and education.

Hydraulic press. This equipment is capable of controlled hot and cold deformation of metallic materials, pressing of metal powders, and extrusion, with a maximum force of 2500 kN.

Fritsch PULVERISETTE 7 Premium line planetary mill with 2 grinding stations is designed for a wide range of applications and is ideal for loss-free grinding of hard, medium-hard and brittle materials to a final size of 50 nm. Depending on the desired final size, grinding can be carried out dry, in suspension or in inert gas. In addition to milling, it can be used for mixing and homogenizing emulsions and pastes or for mechanical activation and alloying in materials research.

PVD (Physical Vapor Deposition) (AJA International - ATC Series) system for obtaining thin films by magnetron sputtering, with the possibility of DC and/or RF deposition, reactive or non-reactive deposition, using a maximum of 3 magnetrons equipped with 38.1 mm (1.5 inch) diameter targets up to 75 W. There is the possibility of rotating and heating the substrate during deposition.

Experimental laboratory setup for thin film deposition using PVD (Physical Vapor Deposition) processes. The system is equipped with RF, DC, DC-Pulsed, and thermal vaporization deposition sources, allowing for reactive and non-reactive depositions. The system can monitor the deposition rate using a quartz microbalance. For sputtering deposition, it uses 4-inch magnetrons (2 pieces) and 2-inch variable angle magnetrons (2 pieces).

Ossila Spin Coater equipment for thin film deposition, with a rotation speed range of 500–10,000 rpm, rotation speed stability < 0.25%, and rotation time range of 1–3,600 seconds. The substrates can have maximum dimensions of 100 mm (4″). The substrate support design can accommodate substrate sizes of 20 mm × 15 mm, 25 mm × 25 mm, 50 mm × 50 mm, and 75 mm × 25 mm.

Ossila Dip Coating Equipment for thin film deposition, with a minimum substrate moving speed of 0.05 mm∙s-1 and a maximum substrate moving speed of 125 mm∙s-1. The integrated software allows the equipment to be operated manually or automatically and enables the independent setting of substrate immersion and withdrawal parameters to facilitate the deposition of layers with constant or variable thickness.

Biosan Orbital Shaker-Incubator ES-20 – compact laboratory equipment, ideal for mixing and incubating biological liquids (cell cultures, biological materials, extracts), with full digital programming.

Prestige Medical 2100 Classic Autoclave is a portable table-top sterilizer designed for sterilizing unwrapped solid instruments, frequently used in fields such as general medicine, dentistry, research, etc.

Nahita Model 2615 centrifuge is an angular rotor equipment with a capacity of 6–8 tubes × 15 mL, with maximum speed of 4,000 rpm, with electronic speed and time control.

Velp Scientifica Classic Vortex Mixer (Advanced) – compact orbital mixer with variable electronic speed control up to 3,000 rpm, touch and continuous operating modes, robust zinc and technopolymer structure with stable base, IP 42 protection, universal operation (100–240 V), interchangeable accessories.

C-MAG HS 7 (IKA) is a heating magnetic stirrer equipped with a ceramic heating plate for excellent chemical resistance. It stirs volumes of up to 10 liters (H₂O) with a powerful motor and offers precise temperature control up to 550 °C.

SLS Center sPro (3D Systems) is a 3D printing system based on Selective Laser Sintering (SLS) technology, which uses a laser to fuse powdered material (polymeric, ceramic, metallic) and build three-dimensional parts, layer by layer. The laser traces the outline of each cross-section of the 3D model onto a bed of powder, which is then hardened by localized melting. After each layer has solidified, the build platform descends, and the process is repeated for the next layer until the part is complete. This method allows for the creation of complex parts with high mechanical strength and precision, without the need for additional supports.

Raise3D Forge1 is an industrial 3D printing system based on FFF (fused filament fabrication) technology, designed for the manufacturing of high-strength metal parts. Using BASF Ultrafuse® 316L and 17-4 PH metal filament, Forge1 enables the development of complex parts with superior mechanical and thermal strength, suitable for rapid prototyping and small series production. The system features a build volume of up to 300 × 300 × 300 mm and allows dual extrusion, facilitating the use of support materials for complex geometries. It is compatible with the MetalFuse process, which includes catalytic polymer removal and sintering, ensuring high-quality final metal parts.

Peopoly Phenom XXL V2 is a large-format 3D printer designed for industrial production of photopolymer resin parts. It uses MSLA (Masked Stereolithography) technology and has a 23.8-inch industrial LCD panel with 4K resolution (3840 × 2160 pixels). The print dimensions are 527 × 296 × 550 mm, offering significantly higher production capacity compared to other printers in the same range. The printer is equipped with a high-precision parallel LED lighting system, controlled by the new Vlare Core firmware, which ensures uniform light distribution and increased energy efficiency. It is compatible with Lychee Slicer 5.2 software, as well as other applications such as Tango and Vlare Slicer, offering users flexibility in the process of preparing the files for printing.

Phrozen Cure Mega is a professional UV light curing station designed for large-scale 3D printing. Featuring a 40 × 40 × 45 cm chamber, a 405 nm UV light system (90 W total), and a 360° rotating platform, it ensures fast and uniform curing for both oversized models and multiple smaller prints.

PioCreat G5 Pro uses a screw extrusion system to process plastic granules with a diameter of 2–5 mm, offering a printing speed of up to 0.8 kg/h. The printing volume is 500 × 500 × 500 mm. The printer features a build plate heated to 150 °C and an extruder capable of reaching temperatures of up to 450 °C, allowing for the use of a wide range of thermoplastics and composites. These features make it ideal for rapid prototyping, small batch production, and industrial customization.

CreatBot DX Plus uses FDM/FFF technology and has a build volume of 300 × 250 × 520 mm, allowing large parts to be created in a single session. It is equipped with a screw extrusion system capable of reaching temperatures of up to 350 °C and a build plate heated to 120 °C. These features allow for the use of a variety of materials, including PLA, ABS, PETG, PVA, HIPS, and carbon fiber composite filaments.

Shining 3D EinScan Pro HD is a portable 3D scanner that provides accuracy up to 0.04 mm. It can perform fast and detailed manual scanning, as well as fixed scanning with a rotating stand. It is equipped with an LED sensor and offers multiple alignment modes, including markers and texture.

Delta WASP 2040 Clay system is a compact, open-frame design for precise and fast printing with ceramic paste. Using LDM (Liquid Deposition Modeling) technology, it can print objects up to 40 cm high, with a print volume of Ø200 × 400 mm. Compatible with various ceramic materials, it offers nozzle options from 1.5 mm to 3 mm. The printer operates at speeds of up to 150 mm/s, with a maximum layer resolution of 0.5 mm.

Mayku FormBox is a desktop thermoforming device that uses vacuum to create detailed shapes from various thermoplastic materials. Ideal for rapid prototyping, education, and small-batch production, FormBox can be used to make molds for casting concrete, resin, chocolate, plaster, and more.

Bambu Lab X1C is a prosumer/professional-grade 3D printer. Based on a closed CoreXY chassis, it offers advanced automation through Lidar sensors (bed leveling calibration, initial layer verification), artificial intelligence for failure detection (spaghetti detection), and automatic dual-system leveling (Lidar + force sensor).

Noztek Pro is a reliable, entry-level analog filament extruder designed for research, education, and manufacturers. Built with a stainless-steel barrel and screw and powered by a high-torque planetary gear motor, it ensures consistent extrusion for both pellets and powdered polymers. It can process various polymer blends with different reinforcements.

Materials characterization

Nikon Eclipse MA100 is a compact, inverted metallurgical microscope designed for routine inspection of industrial materials and parts. It is particularly suitable for applications in production, quality control, and research and development.

Leica Emspira 3 is a versatile digital microscope designed for rapid visual inspection and accurate documentation of samples without the need for a dedicated computer. It offers high-resolution images and an intuitive interface, facilitating collaboration and increasing efficiency in industrial and research environments.

Hirox HRX-01 high-resolution digital microscope offers a 5 MP CMOS camera at 50 fps with Live HDR technology and automatic image optimization, perfectly suited for detailed 2D and 3D imaging. It offers a magnification range from 20X up to 5000X.

Mechanical testing equipment. It allows for the determination of mechanical behavior (tensile, compression, bending) on standardized and non-standardized test specimens by configuring the software program, both at high temperatures ranging from room temperature to 1200 °C and at low temperatures ranging from -150 °C to 0 °C.

CV 700 universal hardness tester is a compact device designed for fast and accurate measurement of metal hardness using Rockwell, Brinell, and Vickers methods.

CSM Instruments NHT2 nanoindentation module. It is used to determine the mechanical behavior of surfaces by indenting at nano-micro depths. The maximum load is 500mN, and the minimum load applied to the indenter is less than 0.05mN. It can be used to characterize hard or soft, organic or inorganic materials or coatings.

Micro Scratch Tester (MST) from CSM Instruments is a device used to characterize the adhesion and mechanical resistance of thin films (organic, inorganic, soft, or hard) by controlled scratching with a diamond tip, monitoring the force and indentation depth in real time.

Equipment for determining the thickness of thin films (CSM Instruments Calotest). It can be used to analyze coatings with thicknesses between 0.1 and 10 µm. Typical coatings that can be analyzed include CVD, PVD, plasma coatings, anodic oxide layers, ion-sputtered or ion-plated surfaces, electroplated coatings, polymers, paints, and lacquers.

Future-Tech FM 700 Microhardness Tester (Micro Vickers) is a device designed for accurate hardness measurement on fine surfaces, using loads between 1 and 1000 gf (9.8–9807 mN) and diamond indenters with Vickers or Knoop geometry.

The tribometer from CSM Instruments is used to measure the coefficient of friction and wear rate between pairs of materials, as well as to carry out lifetime analyses. It is based on the pin-on-disc principle. The maximum rotation speed is 600 rpm and the maximum applied load is 20 N.

Linseis LS PT L75 HD 1400 C dilatometeris a high-precision laboratory instrument used to determine dimensional changes (ΔL) in solid materials during heating or cooling, capable of analyzing two samples simultaneously.The device operates over a wide temperature range, from room temperature to 1400 °C, and allows measurements to be carried out under various controlled atmospheres (air, vacuum, or protective gases), thus providing essential data for characterizing the thermal behavior and structural changes of materials

STA 449 F3 Jupiter (NETZSCH) system is an integrated advanced thermal analysis device designed to carry out simultaneous thermal analyses (DSC – differential scanning calorimetry, DTA – differential thermal analysis, TG – thermogravimetric analysis). The device allows for the complete characterization of materials by simultaneously measuring mass changes and heat flow over a wide temperature range (RT – 1600 °C) and under controlled atmospheres (air, vacuum, or protective gases). The versatility and accuracy of this system make it essential for studying transformation processes, thermal stability, chemical reactions, and structural properties of materials.

DSC 200 F3 MAIA (NETZSCH) is a high-precision differential calorimeter designed to measure the heat flow associated with thermal transformations of materials. The device allows the characterization of thermal properties such as melting points, crystallization, glass transitions, chemical reactions, and thermal stability over a wide temperature range (-150 °C to 600 °C) and under controlled atmospheres (air, vacuum, or protective gases). The system provides fast, reproducible, and automated analysis, which is essential for research and development in the field of materials.

SPECTROMAXx is an arc/spark optical emission spectrometer (OES) designed for fast and accurate elemental analysis of metals in industrial environments such as foundries and metal fabrication plants

Dynamica Halo XB-10 spectrophotometer scans solutions in the wavelength range λ = 190–1000 nm. Operating modes include photometry, multiple wavelength analysis, spectral scanning, temporal scanning, kinetics, and direct concentration results.

The portable spectrophotometer (3nh ML-YS45140) is a compact device for measuring color parameters (reflectance) according to CIE/ISO/ASTM standards, with SCI and SCE measurement modes, USB/Bluetooth connectivity, color touch screen, battery powered, internal storage memory, and high accuracy (ΔE* ≤ 0.06).

Liebisch KBEA 300 accelerated corrosion chamber operates with a conventional water bath and works in a temperature range from room temperature to a maximum of 45 °C. It also features an automatic ventilation system that allows accelerated corrosion tests to be carried out automatically in a sulfur dioxide atmosphere, in accordance with ISO 22479:2019 Corrosion of metals and alloys — Sulfur dioxide test in a humid atmosphere (fixed gas method).

Palmsens EmStat Blue is a small, low-cost potentiostat with research-grade capabilities. It has eight current ranges from 1 nA to 100 mA (EmStat3+ Blue) at full scale, with a minimum resolution of 1 pA. It offers the most relevant electroanalytical measurement techniques and is used with PSTrace software or PStouch for Android.

Drop Shape Analyzer – (manual mode) from KRÜSS is a contact angle measuring instrument used for the rapid and accurate evaluation of the wettability of solid surfaces. In manual mode, the operator applies a drop of liquid to the sample, and the high-quality optical system captures its image to determine the static contact angle. This main function allows the characterization of hydrophobic or untreated surfaces, respectively the characterization of wettability on different materials (plastic, glass, ceramics, wood, paper, metal).

HOLMARC impedance tube is based on the transfer function method, which separates incident and reflected energy from the measured transfer function and then estimates the acoustic properties of the analyzed sample. The properties measured using this test method are useful in basic research and development of sound-absorbing materials.

Metria M51 is a laboratory instrument for accurate measurement of conductivity (0.01 µS/cm – 20.0 mS/cm) and TDS (Total Dissolved Solids) (0–200 ppt), with automatic temperature compensation, illuminated LCD display, flexible calibration (1–3 points), intuitive user interface.

Metria M21 – pH/mV Meter: table-top laboratory device for measuring pH and redox potential (mV), with automatic multi-point calibration, automatic temperature compensation, illuminated LCD display, and precise and stable operation, suitable for chemical and biological analysis applications.

Ossila 4-point multimeter is a professional instrument designed for high-precision resistance measurements using the Kelvin (4-wire) method. Unlike standard (2-wire) measurements, the 4-point method eliminates the effect of cable and probe resistance, providing extremely accurate values — ideal for laboratory and research applications in the field of advanced materials and electronics.

Agilent E4991A is an RF impedance and material analyzer operating in the 1 MHz to 3 GHz range (1 mHz resolution) with a basic accuracy of ±0.8%. It uses RF-I-V technology for highly accurate measurements on a wide range of components, including SMDs and dielectric or magnetic materials. Optional: DC bias (±40 V/50 mA), material measurements, temperature characterization, and connection to the test station.

Agilent N6705B – Modular DC Power Analyzer: compact system (4 slots, up to 600 W total) that combines power supplies, digital multimeter (DMM), oscilloscope, arbitrary waveform generator, and data logger, all in a single device. It allows direct operation from the front panel or control from a PC (GPIB, USB, LAN interfaces, LXI Class C compliant), ideal for research and development.

Agilent N9020A MXA Signal Analyzer – high-performance RF/microwave signal analyzer with a frequency range from 10 Hz to 26.5 GHz, 25 MHz analysis bandwidth (standard), expandable to 160 MHz. Ideal for development and testing in areas such as wireless communications, IoT, and complex signal testing applications.

The Agilent N5181A MXG is a high-performance analog RF signal generator with an operating frequency range of 100 kHz to 6 GHz. It provides an output power of +23 dBm at 1 GHz, with a phase noise of ≤−121 dBc/Hz at 1 GHz and 20 kHz offset. It supports AM, FM, PM, and pulse modulations, as well as fast frequency and amplitude switching. It is ideal for research and development applications, production testing, and signal simulation in analog communications.

The Agilent B2912A Precision Source / Measure Unit (SMU) is a 2-channel, compact, and cost-effective bench-top SMU with the capability to source and measure both voltage and current. It is versatile to perform I/V (current vs. voltage) measurement easily with high accuracy. The integration of 4 quadrant source and measurement capabilities enables I/V measurement simply and easily without configuring multiple instruments.

Struers LABOTOM 3 is an easy-to-use and powerful cutting machine that can process a wide range of shapes, sizes, complexities, and materials.

Buehler Phoenix Beta - Automatic single-plate polishing machine with a 200 mm platen, designed for preparing single or multiple metallurgical samples.

Struers Laboforce-3 is an automatic sample displacement device designed for use with Struers polishing machines. It allows simultaneous preparation of up to 6 samples, ensuring consistent force application and reproducible results in metallographic sample preparation. Struers Labopol-5 is a high-performance automatic polishing machine for metallographic sample preparation. It supports single or multiple samples, delivering consistent and reproducible results with precise control of force and speed.