Infrastructure

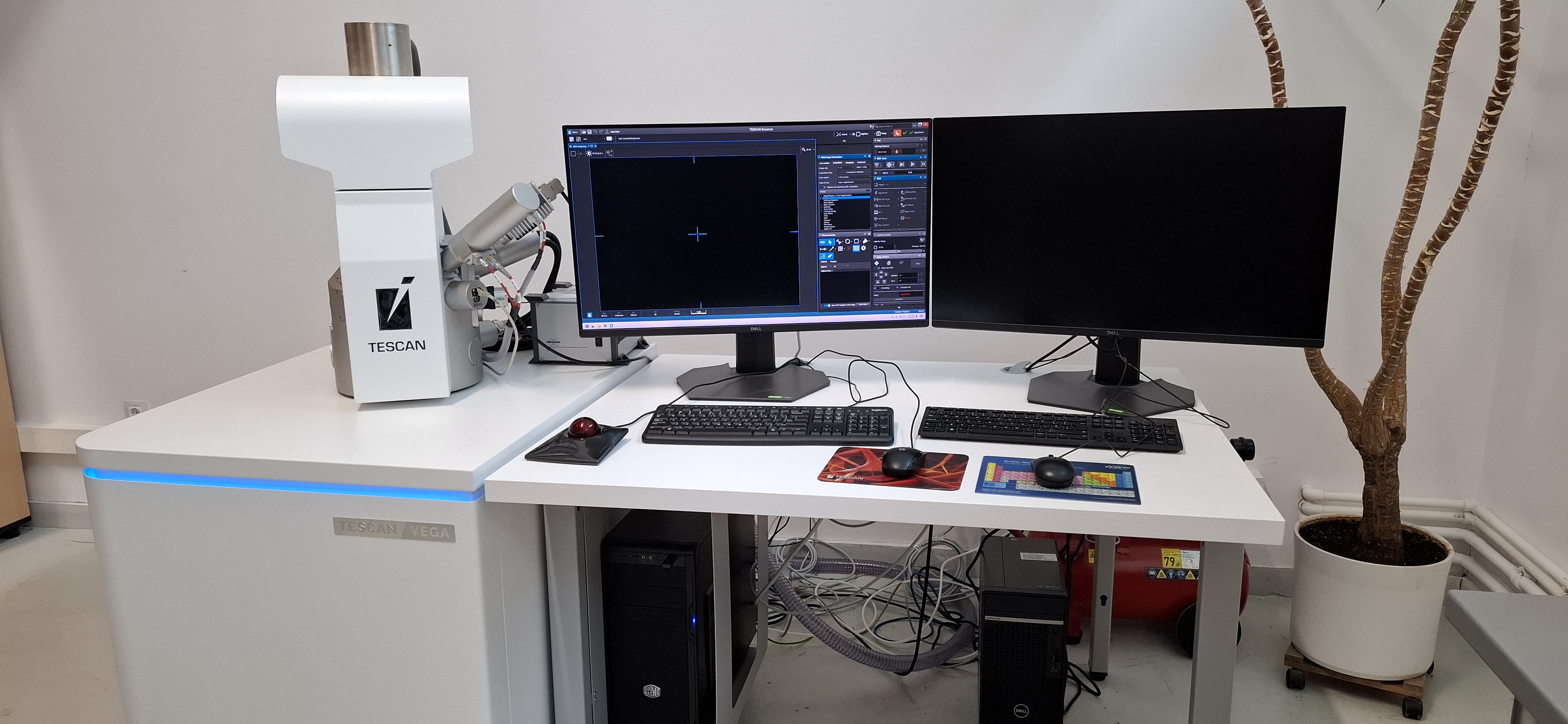

• Scanning electron microscope SEM TESCAN VEGA LMU

The SEM TESCAN VEGA LMU scanning electron microscope is an analytical instrument designed for advanced materials characterization at micro and nanometric scales. The system uses a thermionic tungsten cathode source and is equipped with an Everhart Thornley secondary electron detector mounted in the chamber, together with an EDS and EBSD detector system manufactured by Bruker. The standard size analytical chamber allows operation in both high vacuum and low vacuum modes, up to 500 Pa, enabling the investigation of non conductive samples without charging effects. The equipment includes a motorized five axis goniometer with precise X, Y, and Z movements and provides a spatial resolution of up to 3 nm at 30 keV in high vacuum conditions.

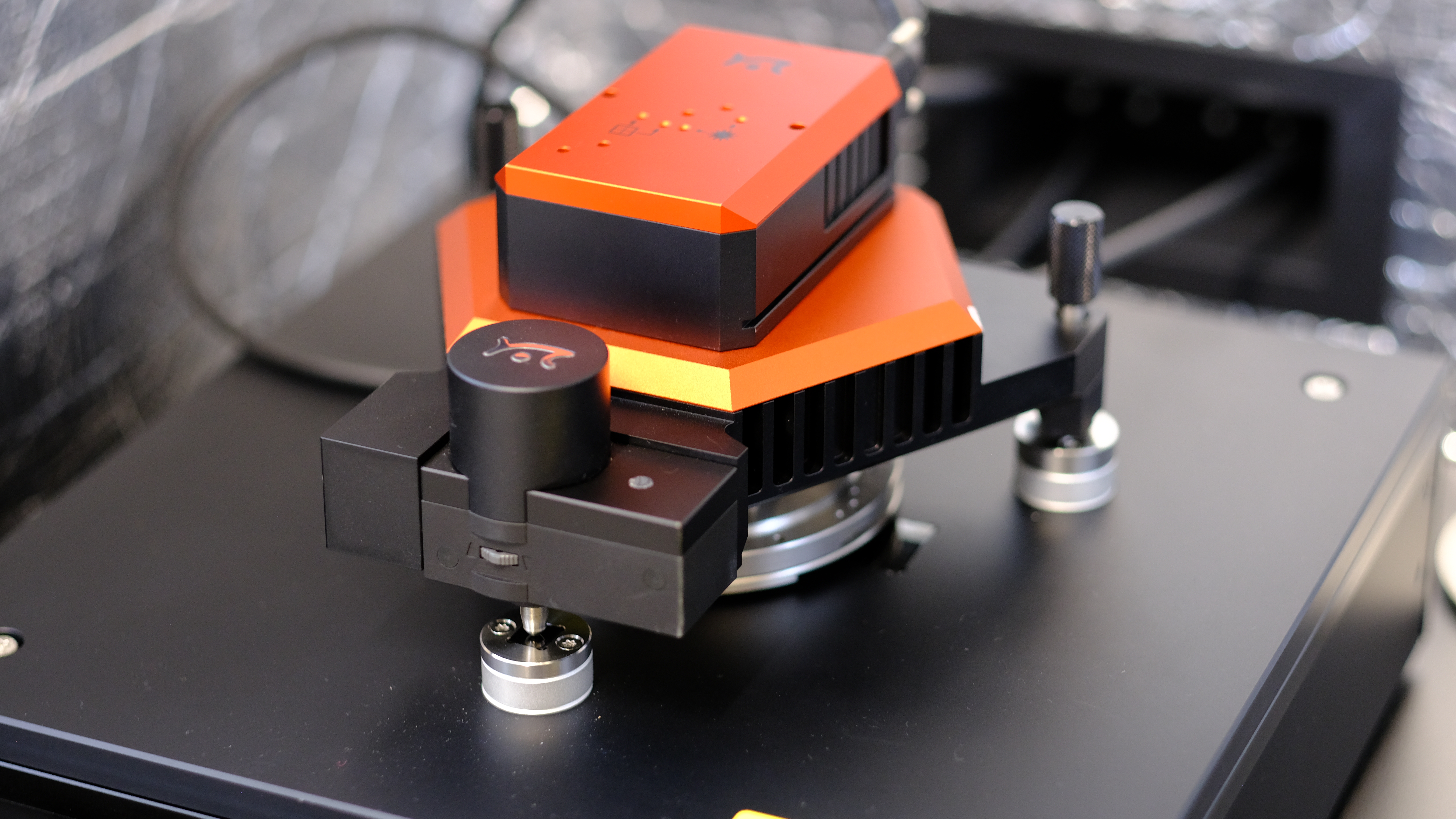

• Atomic force microscope FlexAFM v5+

The FlexAFM v5+ atomic force microscope from Nanosurf is a high precision characterization system dedicated to topographical and functional surface analysis at the nanometric scale. The tip scanning architecture, based on an XY flexure guided scanner with a decoupled Z actuator, enables a scan range of up to 100 μm x 100 μm x 10 μm, with sub nanometer resolution. The system does not require laser alignment due to the integrated alignment structure on the cantilever chip and the high precision cantilever holder. FlexAFM v5+ is equipped with a low coherence 650 nm laser and a four quadrant photodiode detector, ensuring high measurement stability and low noise during operation.

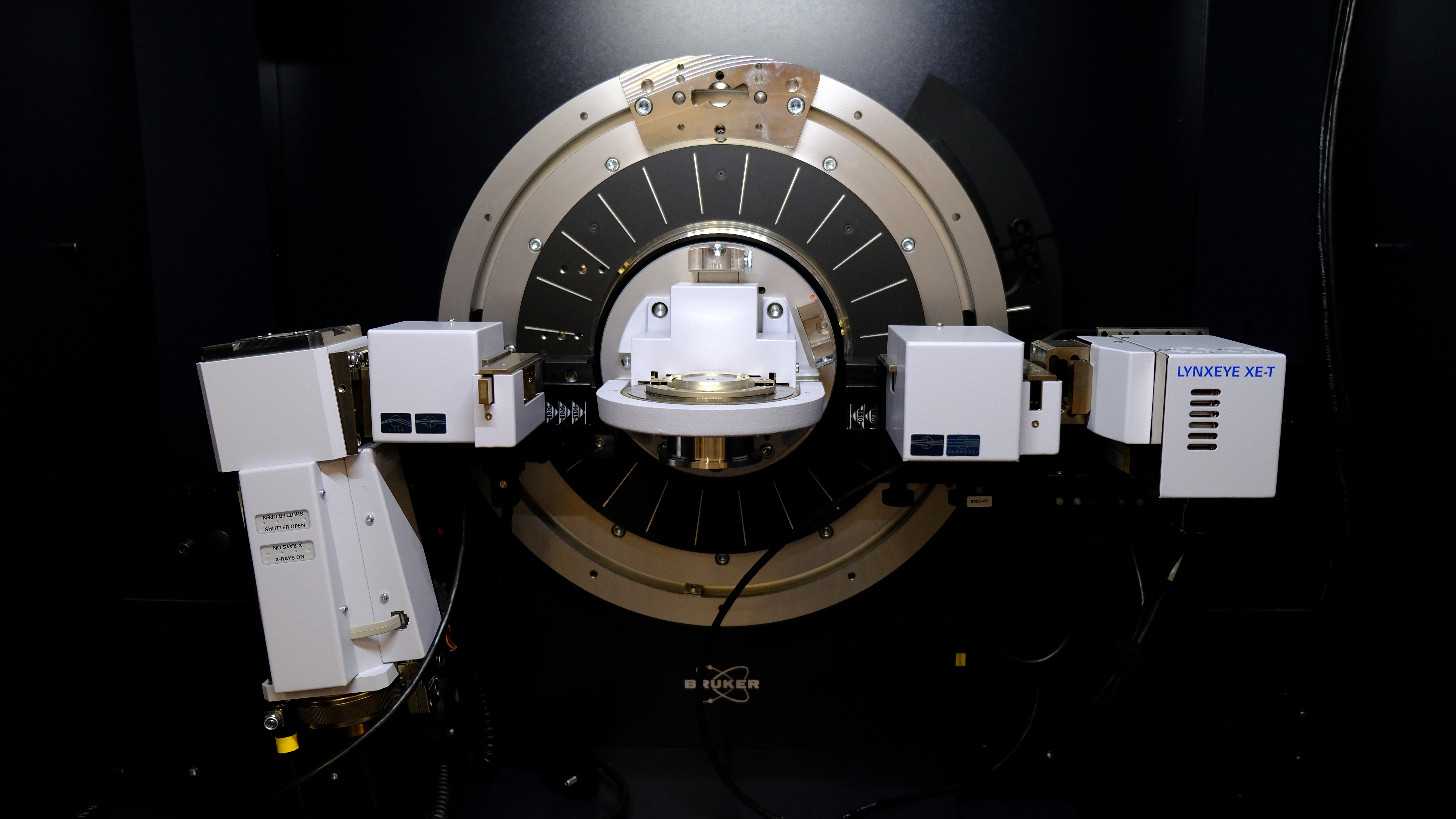

• X ray diffractometer D8 Advance, Bruker AXS

The D8 Advance X ray diffractometer manufactured by Bruker AXS is dedicated to structural and phase analysis of crystalline materials. The system allows measurements in Bragg Brentano geometry for conventional powder diffraction as well as in parallel beam Debye Scherrer geometry, with fully automatic switching between focusing modes without operator intervention. The diffractometer operates at a power of up to 3 kW, with adjustable tube voltage between 20 and 50 kV and anodic current from 5 to 60 mA, providing high flexibility for a wide range of applications. The instrument is equipped with a copper Long Fine Focus X ray tube and a fast LynxEye XE T detector, ensuring high angular resolution, excellent reproducibility and high detection efficiency.

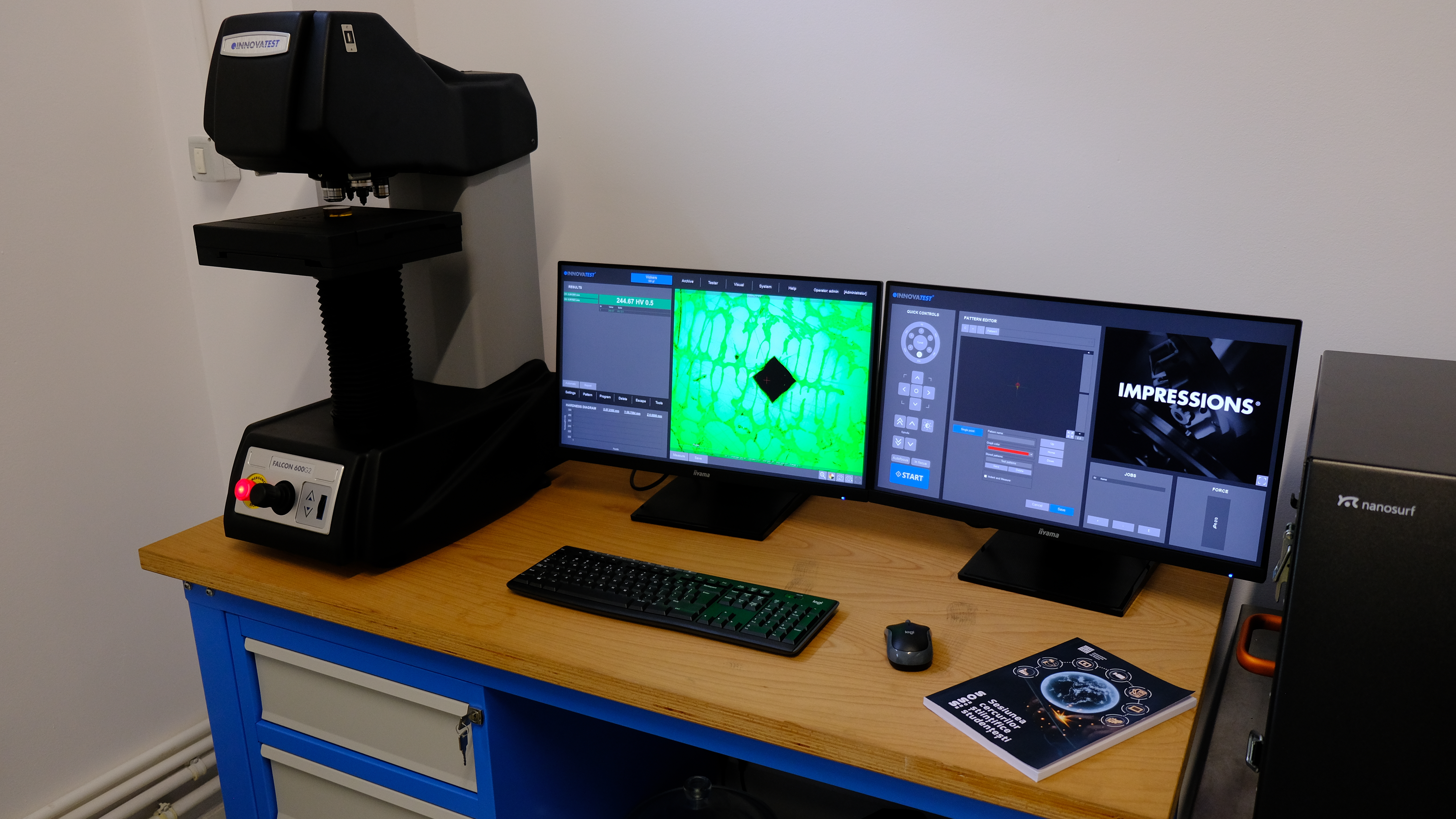

• Microhardness tester FALCON 600FA G2

The FALCON 600FA G2 microhardness tester from INNOVATEST is designed for micro and macro hardness determination using the Vickers, Knoop, and Brinell methods. The system covers a wide test force range, from very low loads up to high loads, between 0.1 gf and 62.5 kgf, enabling precise characterization of metallic materials, ceramics, and thin coatings. The instrument is equipped with a motorized turret with multiple positions for indenters and objectives, a high resolution color optical system for indentation analysis and a CCD camera for wide field sample visualization. The motorized XY stage provides precise and repeatable sample positioning and automated measurements with a travel range of 100 mm x 100 mm and a positioning resolution of 0.001 mm.

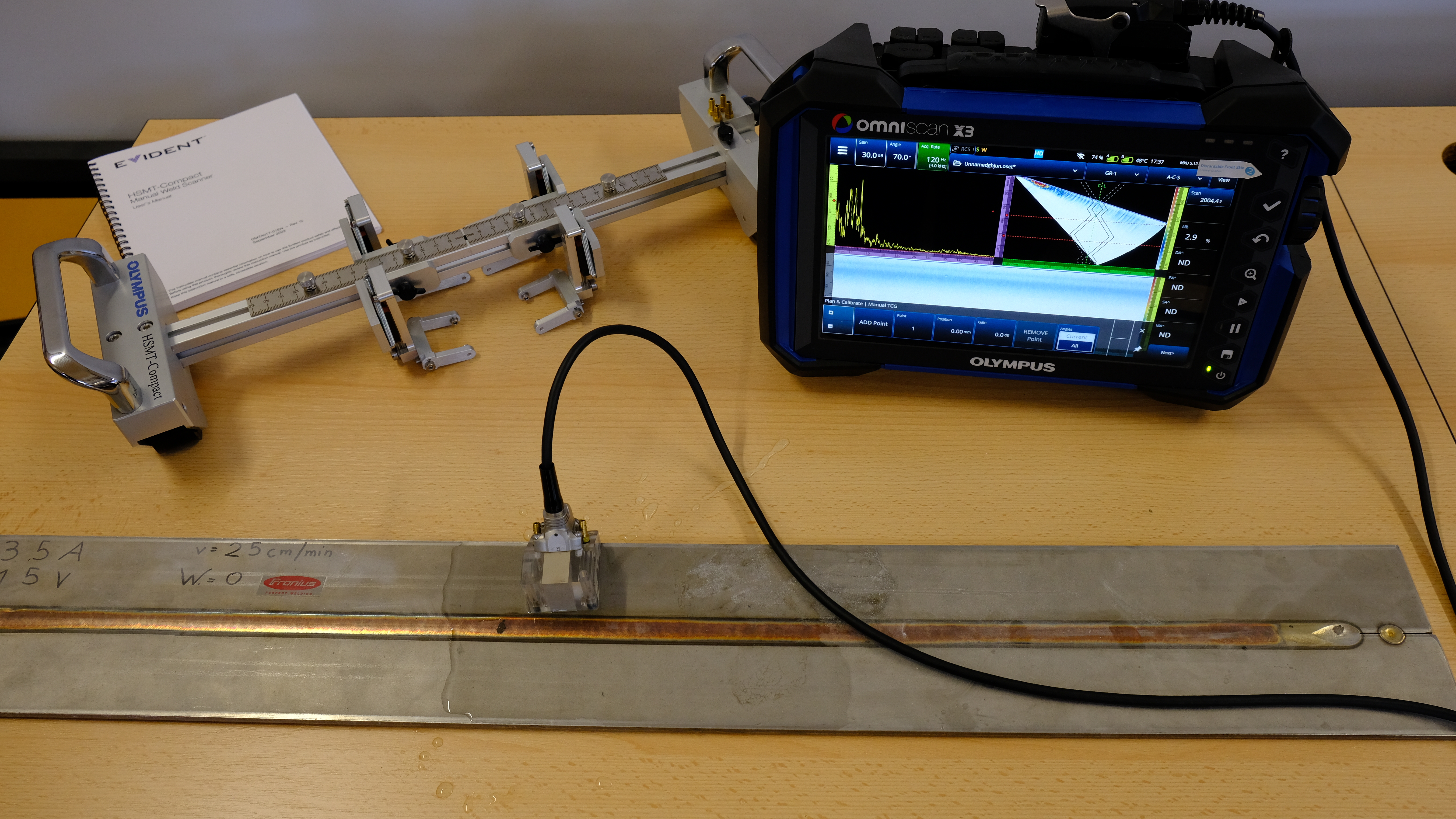

• Ultrasonic flaw detector OmniScan X3 16:64PR

The OmniScan X3 16:64PR ultrasonic flaw detector manufactured by Evident is designed for advanced non destructive testing of materials and industrial components. The system employs phased array and total focusing method technologies for accurate defect detection and detailed internal imaging. OmniScan X3 provides fast data acquisition and real time analysis, supporting reliable and repeatable inspections. The 16:64PR configuration allows the use of up to 32 elements for TFM, two UT or TOFD channels and flexible combinations of inspection groups, contributing to enhanced detection capability and evaluation accuracy.

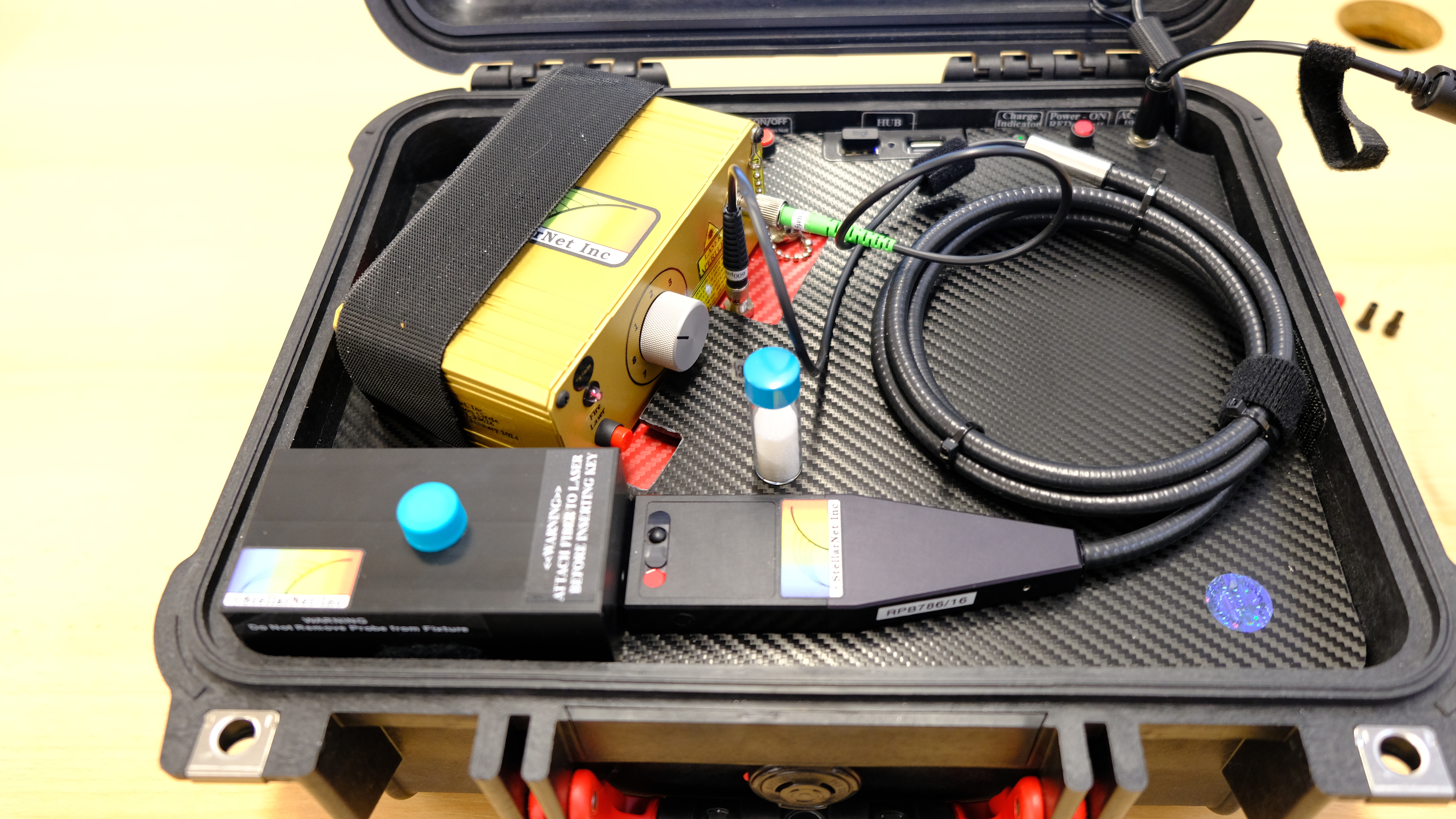

• SERS Raman investigation system StellarCASE Raman

The StellarCASE Raman SERS Raman system from StellarNet is a portable and versatile instrument designed for spectroscopic analysis of solid and liquid samples using Raman and SERS techniques. The system is equipped with two laser sources at 532 nm and 785 nm, with adjustable power, allowing measurement conditions to be tailored to the sample type and required sensitivity. Compatibility with SERS strip substrates enables significant Raman signal enhancement, supporting the detection of compounds at very low concentrations.

StellarCASE Raman provides wide spectral scan ranges for both operating modes, an optical resolution of at least 4 cm⁻¹ and thermoelectrically cooled detectors for improved stability and reduced noise, particularly in the 785 nm configuration. The system is well suited for applied research, chemical analysis and advanced materials characterization.

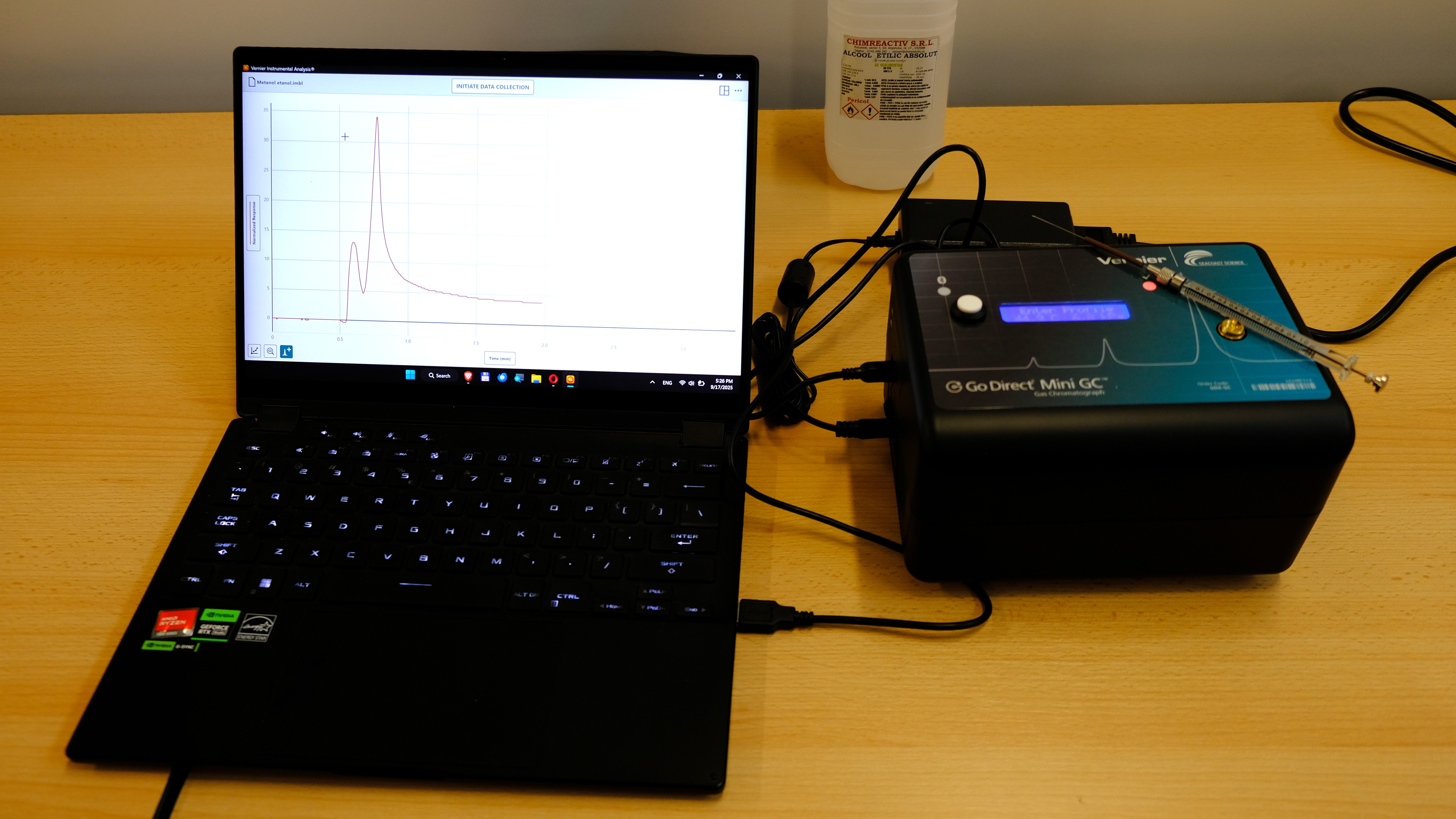

• Portable gas chromatograph

The GO DIRECT® Mini GC portable gas chromatograph from Vernier is designed for fast and flexible gas analysis in laboratory based applied research. The instrument operates using ambient air at room temperature and pressure as the carrier gas, eliminating the need for external gas cylinders and simplifying operation. The separation system is based on a polysiloxane chromatographic column, suitable for separating a wide range of polar and non polar compounds. Column temperature is controllable in the range of approximately 30 to 160°C, with a heating rate adequate for dynamic and rapid analytical measurements.